Overview / Summary

The “Other Specialized Laboratories” at BITS Pilani have been established to advance specialized research and academic initiatives in distinct technological and scientific domains. These laboratories complement the major research centers at the institute and provide targeted facilities for innovation and practical learning in fields like fiber optics, process control, and manufacturing systems.

Vision

To foster niche innovation and applied research by offering specialized lab infrastructure that supports next-generation scientific exploration and industrial development.

Mission

To empower students, researchers, and faculty with access to advanced tools and technologies in emerging areas, bridging academic theory with practical implementation.

Aim & Objectives

- To nurture hands-on technical proficiency in fiber optics, manufacturing, and process systems.

- To support interdisciplinary projects involving cutting-edge hardware and software.

- To promote collaborative research, industry consulting, and prototype development.

Campus

Pilani Campus

Focus areas or Specializations of Center

Fiber Optics: Characterization of optical fibers for communication, including optoelectronic source/detector analysis.

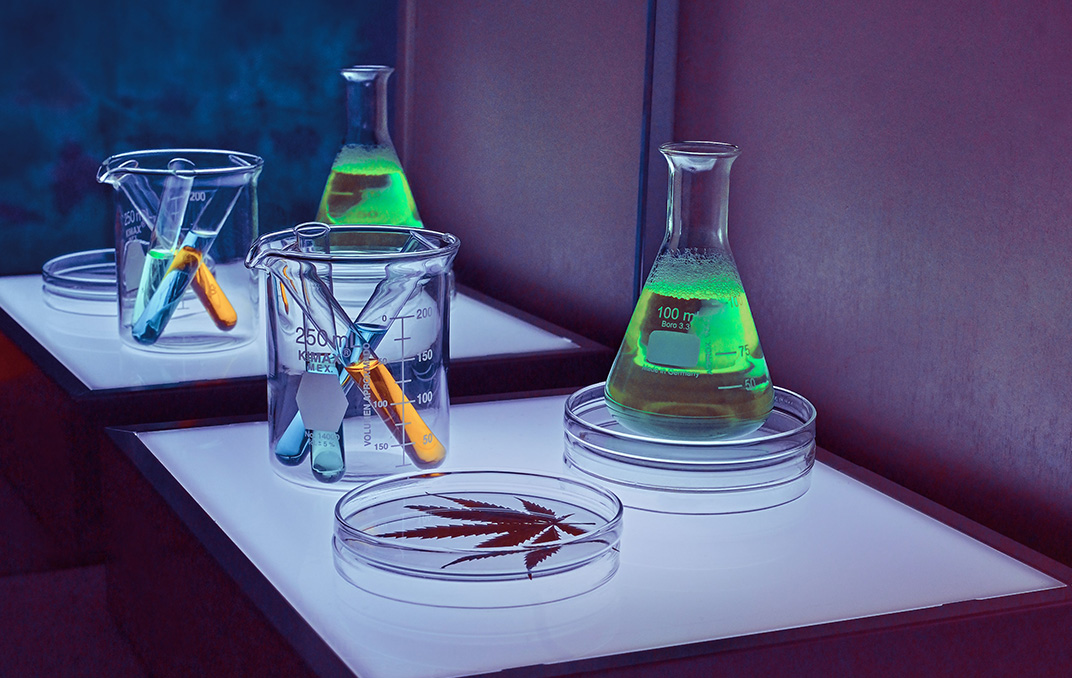

Process Control: Instrumentation for controlling chemical engineering processes such as distillation and heat exchange.

Flexible Manufacturing Systems: Integration of robotics, CNC machining, and computational tools for material handling and modern production techniques.

Process Control: Instrumentation for controlling chemical engineering processes such as distillation and heat exchange.

Flexible Manufacturing Systems: Integration of robotics, CNC machining, and computational tools for material handling and modern production techniques.

Key facilities or Resources provided by the Center

State-of-the-art PC-based instrumentation for optics and sensor development.

Advanced setups for real-time process monitoring and simulation in chemical engineering.

Robotic and CNC tools for hands-on industrial manufacturing research and teaching.

Computational infrastructure to support modeling, control systems, and data analysis.

Advanced setups for real-time process monitoring and simulation in chemical engineering.

Robotic and CNC tools for hands-on industrial manufacturing research and teaching.

Computational infrastructure to support modeling, control systems, and data analysis.

Services

- Custom experimentation and prototyping support for academic research.

- Collaborative access for inter-departmental and industry-sponsored projects.

- Data acquisition, real-time control, and validation for chemical and manufacturing processes.

Training & Workshops

These labs regularly host specialized workshops and training modules aimed at enhancing student and faculty exposure to real-world industrial processes, modern instrumentation, and hands-on software training. Programs are designed to bridge the gap between academic theory and industrial application.